-

2023. May VOL. 662

2023. May VOL. 662

K-water leads the domestic production of ultra pure water by developing ultra water technology, creating infrastructure for technology application and building an industry·academia·research network.

Ultra pure water known as the ‘water of life for semiconductors’ has been spotlighted as a key material used in high-tech industries. Ultra pure water is water that has been purified to the highest levels of purity(with the total organic carbon of 1ppb or less, 1 out of 1 billion, etc). Production of ultra pure water requires the highest-level water treatment technology. Only a few advanced countries have ultra pure water production technology due to the prohibitive initial investment and high entry barriers for corporations in demand for it.

As Korea’s No. 1 export item as of 2020, semiconductors comprise a significantly large portion of the national economy. For South Korea that depends heavily on other countries for ultra pure water production, it is essential to secure stable supply of ultra pure water through domestic production to maintain a competitive edge of its semiconductor industry.

Amid this backdrop, the government has laid the legal framework for the development of strategic high-tech industries including semiconductors by enforcing 「the National Strategic Advanced Industry Act(NASIA)」 in 2022.

With the inclusion of the ‘water industry’ as one of the three green new industries of the year, the Ministry of Environment plans to develop the technology related to materials·parts·equipment for ultra pure water production and the technology required for designing·building·operating ultra pure water production plants so as to create a new growth engine for the national economy and to secure a competitive edge by ensuring a stable water supply for semiconductor production.

In step with government efforts to enhance the competitiveness of the water industry, K-water is playing a leading role in the development of ultra pure water production technology by working with small and medium-sized companies in 2011 and building a pilot plant for the production of ultra pure water for semiconductors in 2013 to facilitate R&D on validation technology. As a result, K-water has applied for four patents on the technologies to predict the breakthrough point of ion exchange resin for stable production of ultra pure water and to reduce the amount of chemicals used. It also developed an operation program to predict in real time the water quality in each production process at the ultra pure water plant, as well as the operational cost. K-water is also involved in producing and supplying de-ionized water to companies that need the water.

In addition, K-water is actively involved in the efforts to secure the technology to produce ultra pure water, including achieving self-sufficiency for ultra pure water technology, training manpower and driving the advancement of domestic industries and technology.

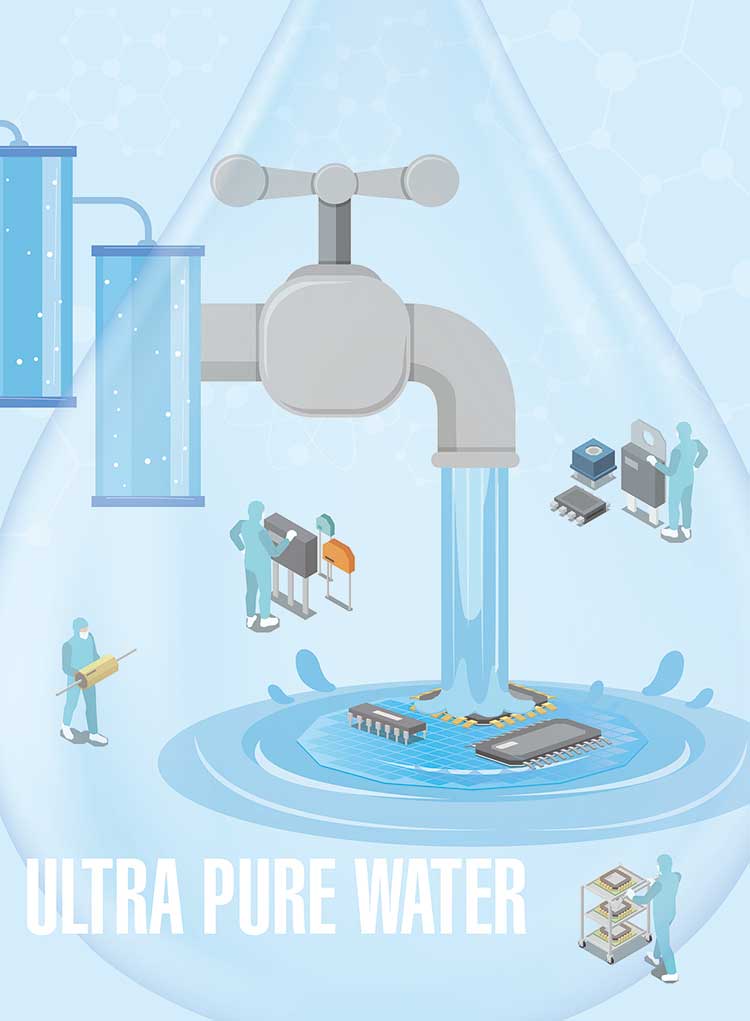

Interior of ultra pure water validation plant

Interior of ultra pure water validation plant

K-water was selected as the organization to conduct research for the ‘development of the technology for design-construction-operation of a high-purity industrial water plant’ as part of the ‘high-purity industrial water production technology development project’ led by the Ministry of Environment. Under the project, K-water started the construction of the ‘high-purity(ultra pure) industrial water validation plant’ at the SK Siltron plant(in Gumi, Gyeongsangbuk-do) in partnership with the Ministry of Environment and Korea Environmental Industry and Technology Institute in November 2021. The construction of the validation plant will proceed in two phases as follows. Phase I includes the development of the three key elements of ultra pure water production(i.e. membrane degassing, ultra violet ray oxidation equipment and ion exchange resin) and the production of 2,400 tons of ultra pure water per day by using imported equipment. In Phase II, the production of ultra pure water will be made possible with the use of domestically produced equipment.

The construction of the facility for Phase I was completed in November 2022, and the test operation was conducted in December. The facility is now ready to produce 1,200 tons of ultra pure water a day. With the Phase II construction of the validation plant slated for completion this year, the integrated technology that combines design-construction-operation of a high-purity industrial water production facility will be developed to ensure domestic production of ultra pure water by 2025.

K-water plans to introduce a digital twin operation system that incorporates cutting-edge technology into its ultra pure water validation plant, and has already published manuals on how to operate the Phase I validation plant.

Interior of the ultra pure water validation plant

K-water is implementing a number of projects to support the growth of ultra pure water industry. In 2021, it made a policy recommendation to create the ‘ultra pure water platform center’ for on/ offline cooperation between the government and the private sector, and started to work on the basic design in 2022 with the completion slated for 2030. The platform center will serve as a hub to achieve Korea’s self-sufficiency for ultra pure water technology as it brings together all the ultra pure water technology-related institutions including a materials·parts·devices-geared performance-testing center, an ultra pure water analysis center, a performance certification center, an ultra pure water plant, a human resources and technology development center, and waste water reuse technology center.

K-water will also work on leveraging the momentum for the growth of high-tech industries including semiconductors, fuel cells and biotechnology and for development of the ultra pure water industry and market, with the ultimate goal of creating the infrastructure for developing ultra pure water technology and an ultra pure water industry ecosystem.

In April 2022, K-water and Samsung Electronics formed an agreement to support the growth of Korea’s ultra pure water industry and under the agreement, the two parties have agreed to collaborate on △driving advancement in the domestic water industry including ultra pure water, by △promoting the efficient use of water resources and △taking initiatives to fulfill ESG responsibilities with respect to water in partnership for securing stable water supplies. In addition, K-water published the first technical manuals related to ultra pure water for training purposes in South Korea in partnership with major universities and ultra pure water companies, and the books are currently being used to train ultra pure water experts.

As the industry leader in the efforts to achieve self-sufficient ultra pure water production, such as developing ultra pure water technology, creating an ultra pure water industry ecosystem, driving the advancement of ultra pure water companies·training manpower in the field, K-water will continue to play a pivotal role in establishing Korea’s presence in the global ultra pure water market.

Semiconductor production process

Semiconductor production process The ultra pure water platform center(plan)

The ultra pure water platform center(plan) Exterior of the ultra pure water validation plant

Exterior of the ultra pure water validation plant