Insight ON

Seawater for Drinking

Seawater Desalination

If you see the Earth from space, more than half of the Earth’s surface looks blue. That is because the ocean covers 70% of the Earth’s surface, and seawater makes up 97% of the Earth’s water. If so, why do we not look for a solution to water shortage in the ocean? Seawater desalination technology was born out of this question.

Text by Editorial Team Sources: Water Supply Research Center, Water Supply Planning Department(K-water)

Seawater, a New Source of Drinking Water

You are having fun on the beach on a warm summer day and then, once in a while, you pause to look at the sea for a while. That’s when you realize there is so much water on Earth, in the ocean to be exact. If we could drink seawater, maybe we could worry a little less about water shortages and the climate crisis. There As we all know, seawater is salty. Seawater is salty because sodium chloride, magnesium chloride and other ions are dissolved in it. Seawater has a salinity of around 3%, while the salinity of our body is 0.9%. We can’t drink seawater as it is, not only because it is too salty to drink but also due to this huge salinity difference. Seawater desalination is a type of water treatment process of removing solvents including salt and turning it into freshwater. Seawater desalination is a major source of alternative water, providing an infinite supply for domestic, industrial, and other uses.

The first-generation desalination technology is distillation. However, as boiling seawater requires large amounts of heat energy, causing greenhouse gas emissions, it is being replaced by reverse osmosis(RO). The RO membrane processes use semipermeable membranes to preferentially induce water permeation through the membrane while rejecting salts. If pressure that is greater than osmotic pressure is applied upon seawater, only water permeates through the membranes and salts and other minerals don’t, thus creating freshwater. The RO method is used by 90% of all seawater desalination plants in the world because it is more productive and economically viable, as well as more energy-efficient than the distillation method.

Tuas Desalination Plant Ⓒ PUB, Singapore National Water Agency

A Stroke of Genius for Coping with Global Water Shortages

Amid the growing population and technological advances, water demand is constantly increasing around the world. According to data released by UNESCO in 2023, water demand is forecast to rise at least 1.5 times overall and around 3 times particularly in the manufacturing sector in 2050, compared to that of 2000. On the other hand, the current water supply system, which heavily depends on rainwater-based dams and rivers, does not guarantee a stable water supply due to accelerating climate change causing extreme droughts and floods. Against this backdrop, alternative water resources technologies including seawater desalination, water reclamation and underground dams are coming increasingly into focus.

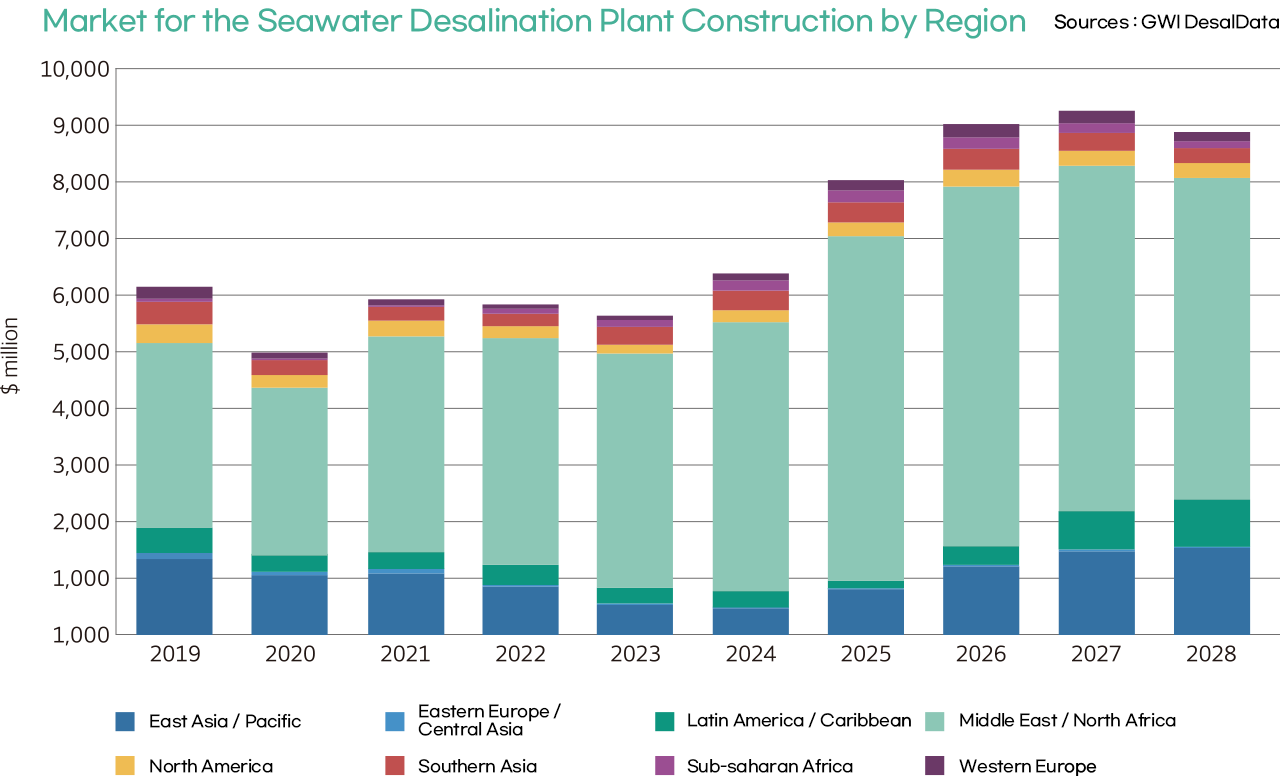

Particularly, the global seawater desalination market is growing at a fast pace. According to data published by GWI DesalData, the global seawater desalination market is projected to reach USD 82.6 billion(USD 16.5 billion on annual average) between 2021-2025, and USD 71.1 billion(approximately USD 23.7 billion on annual average) between 2026-2028. Currently, the largest seawater desalination market in terms of total facility capacity is the Middle East and North Africa. These two regions have large areas of hot and dry deserts, making it difficult to find clean freshwater. For this reason, they are actively involved in converting seawater in the Mediterranean and Arabic Seas to freshwater for domestic uses. Saudi Arabia depends on seawater desalination for over 70% of its water supply and the country’s total desalination capacity is expected to increase to 13,300,000㎥by the end of 2024. Recently, it is becoming more and more important to secure a stable water supply in connection with the construction of Neom City, and in this context, the seawater desalination industry in Saudi Arabia is likely to grow rapidly.

Singapore has long been dependent on its neighboring countries, including Malaysia, for its water supply. However, it has turned to seawater desalination for a solution to meet the rising water demand and reduce its dependence on other countries for water supply. Five desalination plants are currently operating in Singapore with the combined daily capacity of up to 719,000 tons. They are supplying 25% of Singapore’s total water demand and the country is planning to raise the figure up to 30% by 2060.

As the market continues to grow, desalination technology is also evolving quickly. However, the brine discharged from desalination plants contains twice as much salt as natural seawater does, which can pollute the ocean and disrupt the ecosystem. Therefore, countries are developing technologies to minimize brine discharge and promote its reuse. There is also growing interest in reducing carbon dioxide emissions by increasing energy efficiency in desalination processes and utilizing renewable energy sources. Desalination plants around the world are attempting to incorporate digital technologies including AI, big data and digital twin throughout the entire process, from plant design and construction to operation and maintenance.

Time for Korea’s Desalination Technology to Shine

The global desalination market is highly likely to further expand as climate change continues to worsen, dams and other surface water sources are shrinking and demand for industrial water is sharply increasing. Despite this global market trend, however, Korea’s desalination sector is lagging behind due to a low level of social acceptability and regulatory obstacles. As a result, most of the plants in Korea have a relatively small capacity of 100㎥per day and they are operating primarily on islands. Only three plants (POSCO Gwangyang, Gijang-gun in Busan and Daesanimhae Industrial Area in Seosan) are capable of producing 1,000㎥a day.

K-water is expanding its desalination project mainly in coastal areas experiencing water shortages and strengthening the foundation for increasing the desalination capacity by tackling regulatory issues and accelerating R&D efforts to develop core technology. K-water has been building the nation’s largest desalination plant within Daesan Imhae Industrial Area in Seosan, Chungcheongnam-do since 2020 with the total project cost of KRW 311.8 billion. The plant is in the final phase of construction with the competition scheduled for the first half of 2025. Once completed, the plant will be able to supply 100,000㎥of water to the industrial area every day. In addition, talks are under way on the construction of more plants to meet the growing water demand with more factories being built in coastal industrial complexes, including Yeosu National Industrial Complex, the largest petrochemical industrial complex in Korea.

Furthermore, K-water and the Ministry of Environment are working together on a joint research project to revise systems and policies in a way that can facilitate the growth of the seawater desalination industry. Specifically, they are planning to establish the legal basis including policies designed to enhance the profitability of desalination plants, support programs for affected areas and standardization of project phases, as well as for improving the ability to execute desalination projects. Moreover, K-water is actively involved in developing core technologies to save energy in the desalination process through operational optimization and diversification of water sources, and to minimize their impact on the environment by developing uses of brine through collaboration with private companies.

All these efforts are expected to help promote Korea’s seawater desalination industry and eventually export its key innovative technologies to overseas markets.