Live on 2

Domestic Production of Ultra-Pure Water Begins!

K-water celebrates the first domestic production of ultra-pure water

Korea joins the ranks of global leaders in ultra-pure water technology. The supply of ultra-pure water used to depend entirely on other countries, but K-water has developed its own technology to produce ultra-pure water domestically. Domestically produced ultra-pure water is now supplied to semiconductor plants

📝Text by.Editorial Team / 💾Text by. K-water

A new era of domestic production of ultra-pure water

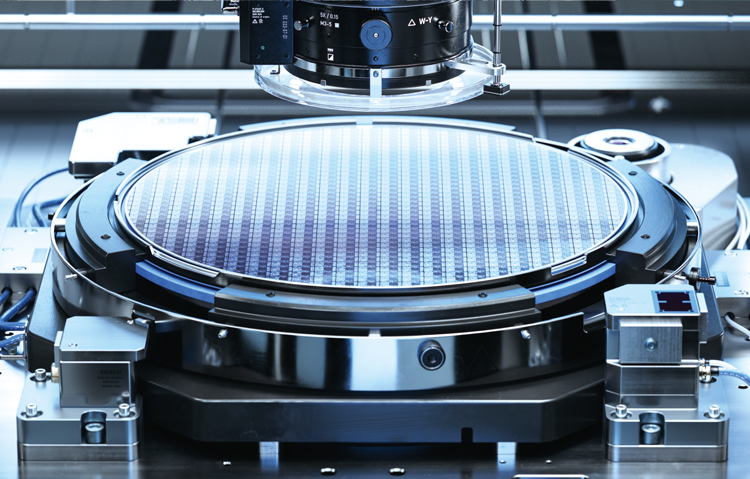

A water-discharging ceremony was held on December 9, 2024 at the demonstration plant for the domestic production of ultra-pure water. This sets a major milestone in Korea’s water technology as industries will be able to use domestically produced ultra-pure water. “Ultra-pure water” means water with almost zero impurities. It is used primarily in the semiconductor production process to rinse contaminants from the surface of silicon wafers. It is also an essential resource used in other hi-tech industries including healthcare, bio, chemical, secondary battery, and display. However, Korea has been dependent on other countries for ultra-pure water production because barriers to the development of advanced water treatment technology are high. The Ministry of Environment and K-water decided to work together on developing the technology for the domestic production and stable supply of ultra-pure water. They built a model plant capable of supplying 25 tons of ultra-pure water a day to conduct research on the design and operation of an ultra-pure water production plant. In recently years, the development of high technology has triggered the reorganization of the global supply chain. In response to this change, K-water has been participating in a research project of the Ministry of Environment since 2021 to expedite the development of ultra-pure water technology. As a result, K-water has built a demonstration plant at the second Gumi plant of SK Siltron and developed the algorithm technology.

All these efforts have brought K-water closer to reaching the goal of domestically producing ultra-pure water. In 2023, K-water supplied 1,200 tons of ultra-pure water a day using domestic technology and imported equipment. In December 2024, the design and operation were done 100% with domestic technology, and K-water succeeded in replacing 70% of the construction technology and core equipment with domestic ones. The ceremony sets a significant milestone as Korea is no longer dependent on the technology of other countries but instead has secured sovereignty in ultra-pure water technology on its own. Following the discharging ceremony, SK Siltron will use 2,400 tons of domestically produced ultra-pure water a day at its wafer plant.

With further research, K-water plans to develop 100% of the core equipment and fully commercialize its ultra-pure technology by having it used at semiconductor plants in Korea and abroad. This way, Korea will build a more solid base upon which it will further hone its competitive edge in the semiconductor industry—a key strategic industry of Korea—and become one of the leading ultra-pure water providers in the global market.