Insight ON

UPW, the backbone for Korea

as a global semiconductor leader

UPW (UPW) is an essential material for the semiconductor industry. Korea has depended on UPW production technology developed in other countries, but is accelerating its efforts to develop its own UPW technology. To this end, K-water, industry, academe, and research are all working together to develop UPW production technology. Why is UPW necessary, and what actions are being taken to ensure that Korea has the technology to produce it domestically?

Text by Editor’s Office

Source by K-water

What is UPW?

Human civilization has gone through different ages including the Stone Age, the Bronze Age, and the Iron Age. Then, in what age are we living now? Have you heard of “Gyuseokki (silicon) Age”? It is a term that has been officially defined by the National Archives of Korea of the Ministry of Interior and Safety. Semiconductor is considered one of the key technologies that has made modern civilization possible, and this is why the term Silicone Age has come about. Widely used in a wide range of everyday electronic devices including smart phones, laptops, refrigerators, and automobiles, semiconductor is also an important material used in future hi-tech industries including self-driving vehicles and drones. For this reason, the semiconductor market is expected to continue growing. In Korea, a country known as a global semiconductor powerhouse, the importance of semiconductor cannot be overstated. Semiconductor accounted for 19.3% of all exports in 2022. Although overall exports have shrunk amid the global economic slowdown, semiconductor exports are rising as prices have begun to rebound recently.

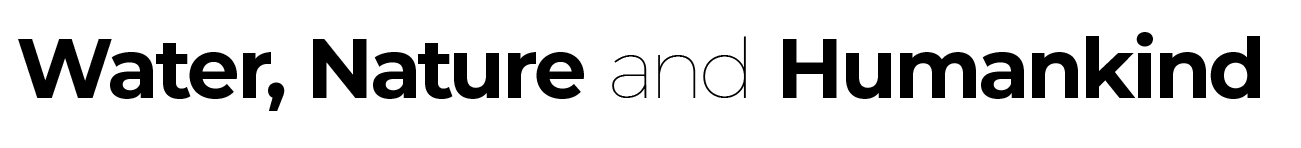

In addition to silicon, there is another key material for semiconductor production: ultra-pure water or UPW. Referring to water that has been treated in multiple steps to the highest level of purity for all contaminant types, UPW is used to rinse off byproducts and contaminants generated in the semiconductor production process. Normal water contains a variety of materials and particles including organisms, minerals, microorganisms, and conductive ion components. When an electronic device gets soaked in water or wet in any way, it causes malfunction. Likewise, even a tiny impurity is not allowed to get into the semiconductor rinsing process, and this is why UPW is used instead of regular water. UPW is not conductive and is almost perfectly clean water.

Domestic development of UPW technology for the further growth of Korea’s semiconductor industry

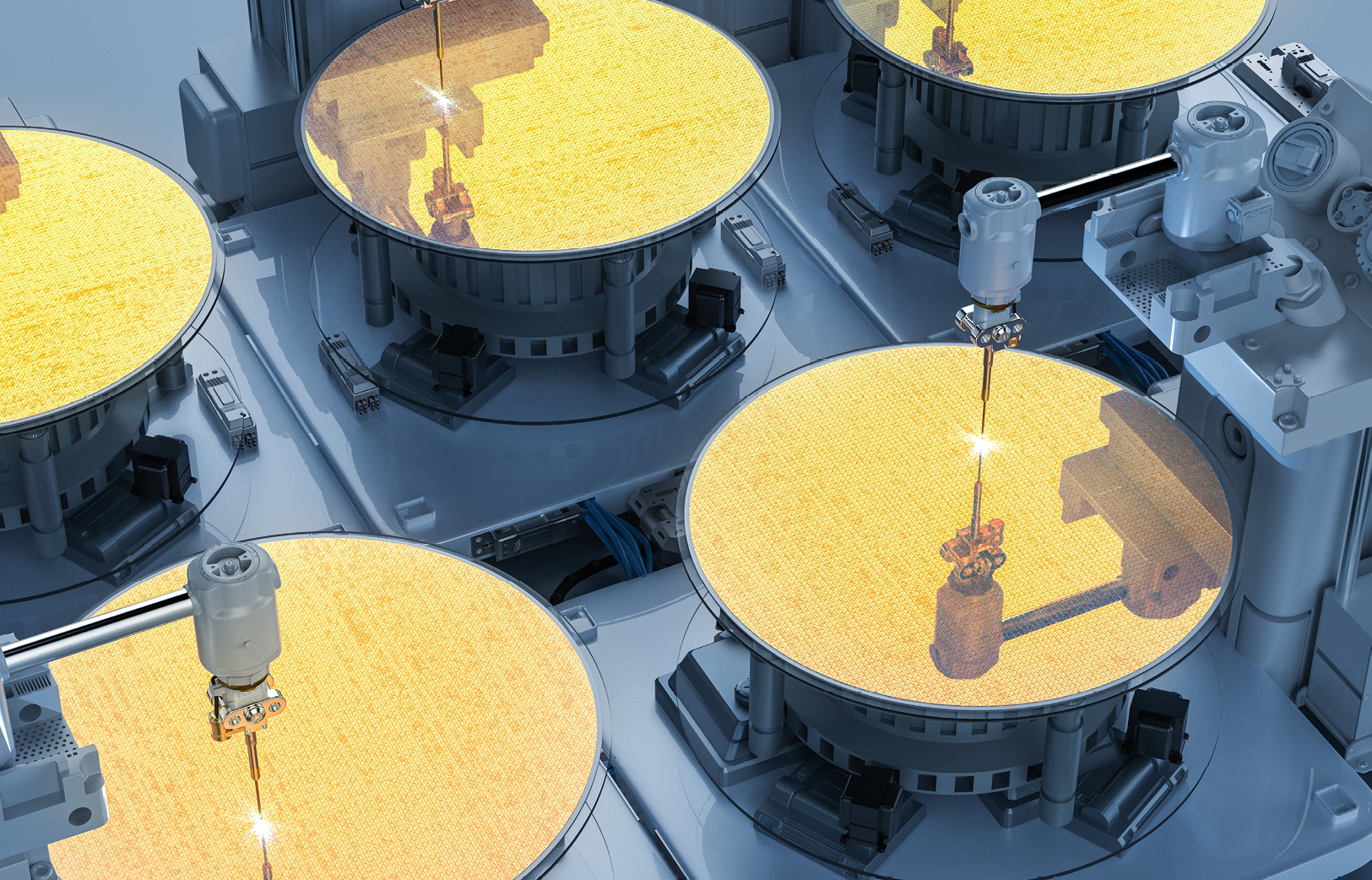

More than 1 ton of UPW is needed to make a six-inch wafer. UPW is essential for semiconductor manufacturing, but Korea has depended on UPW technology developed by Japan, US, and Europe. Japan has been clearly the global UPW technology leader, holding over 56% of the world’s UPW technology patents.

The global UPW market is forecast to grow and reach approximately 23 trillion won by 2024 according to the 2020 GWI Water Data Report. Given the trend, domestic production of UPW is absolutely necessary to secure and promote the sovereignty and competitiveness of the semiconductor industry—one of Korea’s core industries—as well as to secure in advance a competitive edge in the global semiconductor market. However, UPW production requires massive initial investment, with the high market entry barrier making commercially viable mass production difficult; thus impeding and delaying the domestic development of UPW technology.

Against this backdrop, the Ministry of Environment has selected “water” as one of the three major new green industries forming part of the core tasks for 2023. In addition, the Ministry declared its commitment to developing technologies related to UPW materials, parts, and equipment and technologies for the design, construction, and operation of UPW production plants. If Korea successfully develops the technology to produce UPW domestically, it will not only create fresh momentum for the national economy but also help Korea’s semiconductor industry become significantly more competitive by ensuring stable water supply.

From catch-up technology to first-mover technology!

The role of K-water

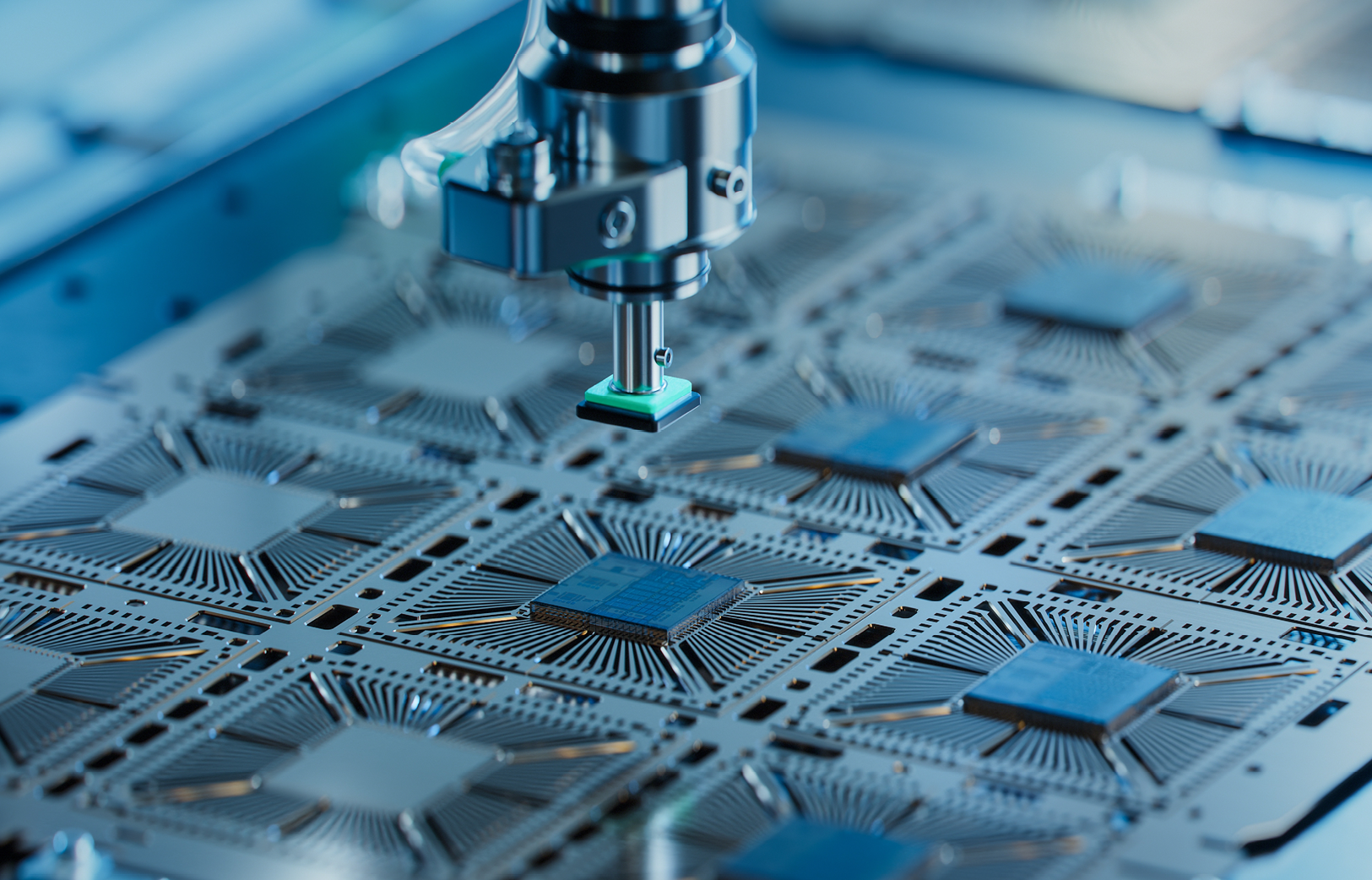

Given the high initial cost and entry barrier, the public and private sectors are working together for UPW technology development under government support. K-water, Korea’s No. 1 water management organization, is also participating in the project. In recognition of its proven track record, K-water was selected as the final research institute for the project to develop the integrated technology for the “design, construction, and operation of high-purity industrial water plants” in June 2021. Subsequently, K-water and Korea Environmental Industry and Technology Institute built a high-purity industrial water (UPW) demonstration plant within SK Siltron in Gumi, Gyeongbuk Province and successfully completed the 1st phase of the construction project in May 2023.

Currently, K-water is supplying 1,200 tons of UPW a day to SK Siltron’s wafer manufacturing facility.

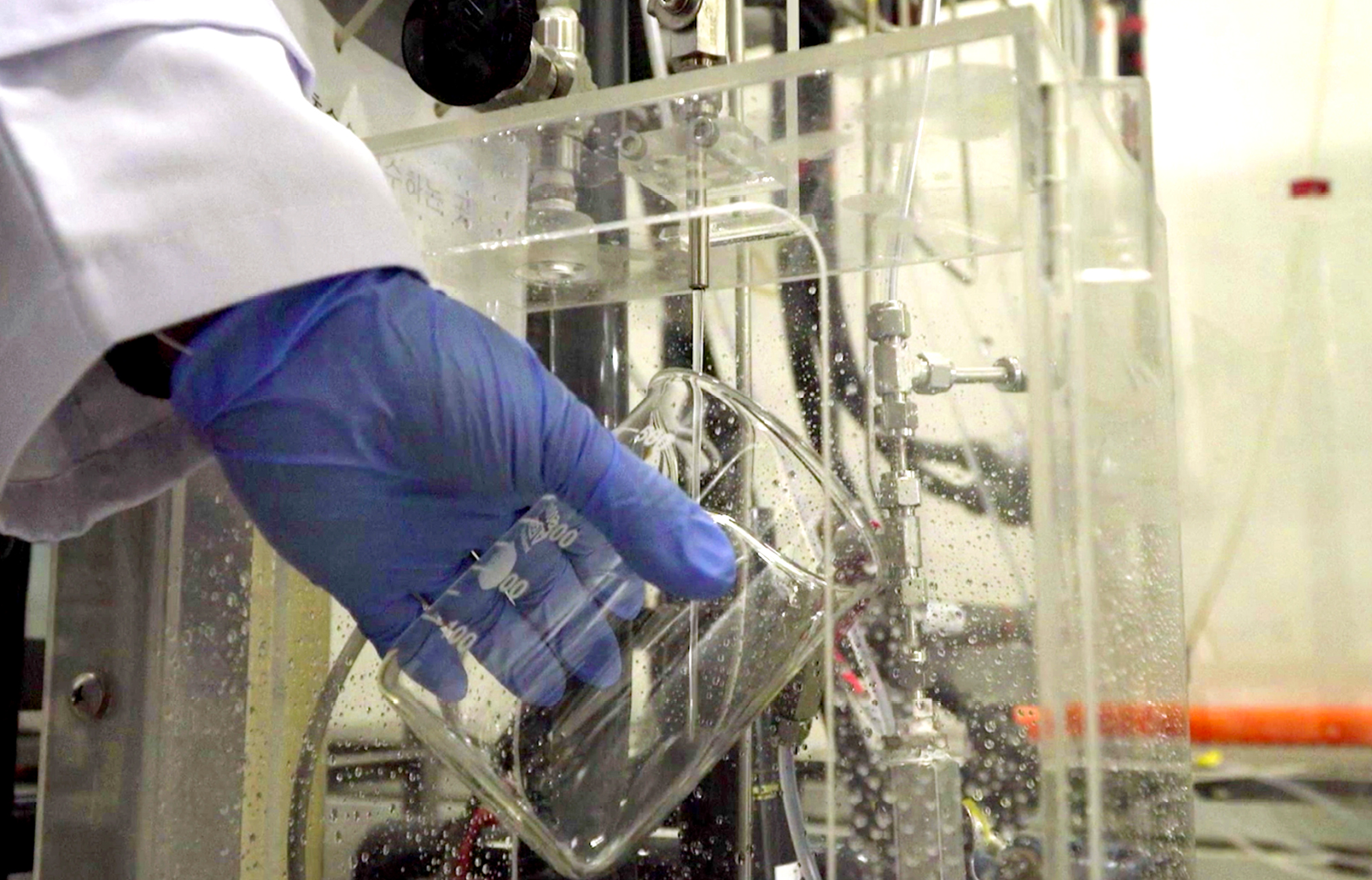

The test-operation and performance test of the 2nd-phase facility will be finished around June 2024. Once the second-phase facility is completed, K-water will be able to produce a total of 2,400 tons of UPW at the facility for supply to SK Siltron’s wafer production plant; thus facilitating the mass production of wafers.

In addition, K-water will integrate a digital twin-based operation system into the demonstration plant. Once developed, it will be the world’s first UPW technology that integrates digital twin and AI. So far, it is known to be more advanced than those of other global corporations leading the UPW sector. K-water plans to obtain third-party performance evaluation and certifications for its UPW technology, which is expected to help bag UPW deals from overseas. Going forward, K-water aims to secure the world’s top-class UPW technology and achieve self-reliance for UPW technology through constant R&D.