Onterview

Elevating Safety and Trust

to the Next Level

Hyclor's vision extends beyond immediate challenges, always seeking the "next level" of safety and reliability. With unwavering determination, Hyclor relentlessly pursues any lingering issues or areas for improvement, even after a solution has been presented. We visited Hyclor, which is relentlessly pursuing a better tomorrow, driven by an unwavering "never-ending" mindset.

Written by Cho Su-bin Photos by Hwang Ji-hyun

Q. What does Hyclor do?

Hyclor is a company dedicated to delivering safe, high-quality tap water nationwide. Through the development of innovative technologies, Hyclor actively contributes to the production and distribution of clean drinking water. Among the myriad hazards lurking within water treatment plants, chlorine gas stands out as a particularly perilous threat. As an essential component in water purification, chlorine gas falls under the category of hazardous materials, demanding stringent regulations for its transportation and storage. To mitigate these hazards, we developed a sodium hypochlorite generating system using an electrolytic tank direct cooling method.

As a result, the company can now manufacture a Type 1 sodium hypochlorite generating system that meets the Ministry of Environment's water treatment standards for the reduction of carcinogenic and anemia-causing substances, outperforming existing products. This innovation paves the way for the production of safer, healthier drinking water. Our company has not only captured an impressive 85% share of the domestic market, supplying water purification facilities to 300 water treatment plants and 200 swimming pools, but has also achieved a remarkable milestone by becoming the first domestic manufacturer to export its sodium hypochlorite generating system to the POSCO Water Treatment Plant in Brazil.

As a result, the company can now manufacture a Type 1 sodium hypochlorite generating system that meets the Ministry of Environment's water treatment standards for the reduction of carcinogenic and anemia-causing substances, outperforming existing products. This innovation paves the way for the production of safer, healthier drinking water. Our company has not only captured an impressive 85% share of the domestic market, supplying water purification facilities to 300 water treatment plants and 200 swimming pools, but has also achieved a remarkable milestone by becoming the first domestic manufacturer to export its sodium hypochlorite generating system to the POSCO Water Treatment Plant in Brazil.

Q. I understand your company has been involved in K-water's tidal power project. Could you elaborate on your specific contributions?

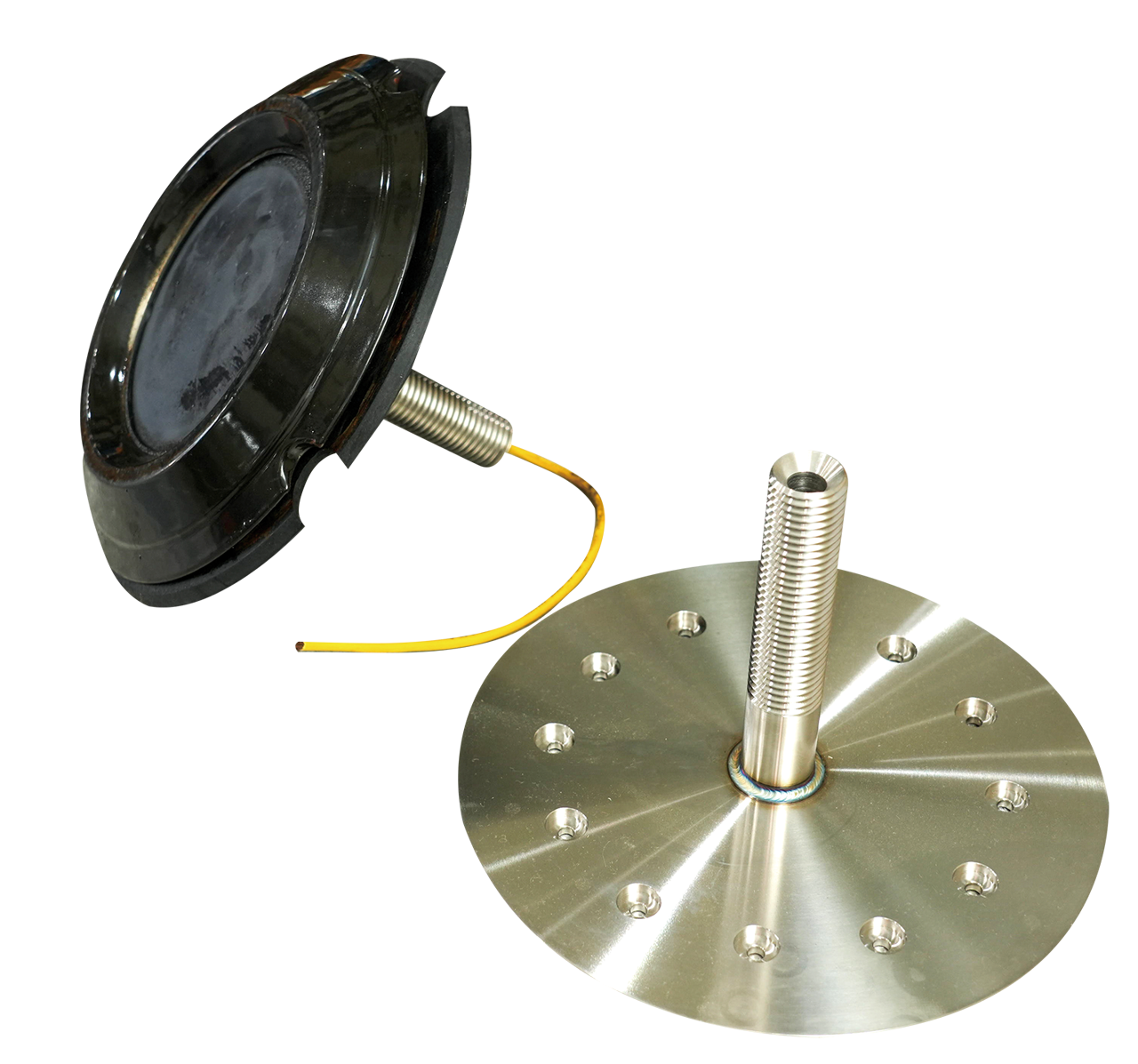

Harnessing the power of the tides, tidal power plants generate electricity by utilizing the flow of seawater into reservoirs to drive turbines. Since the turbine is made of a single massive piece of iron, it naturally starts to rust over time. To combat these corrosion issues, electrodes are strategically placed to monitor and manage rust formation. Still, the strong currents of seawater flowing through the turbines often caused damage to the electrodes due to the ingress of large rocks and debris carried in by the tidal currents and seawater. The paramount challenge was to develop highly durable electrodes as their failure could unleash a torrent of high-pressure seawater. Enhancing safety and durability required a groundbreaking solution. In response to the need for electrodes that could endure harsh conditions such as high pressure and vibrations, stainless steel was chosen as the material for the electrodes.

Q. Believe it or not, it took a staggering eight years to perfect the stainless steel electrodes.

The initial development took about a year. Once we implemented the product in the tidal power plant, however, we stumbled upon several areas for improvement. It took a full eight years of continuous refinement and problem-solving to bring the development to its current level. In recent efforts, collaboration with on-site operators from K-water has led to the adoption of a novel top-coating method using a new material for electrodes, which further enhanced their durability. While renowned for its durability, stainless steel is also susceptible to corrosion. To address this drawback, we are currently developing electrodes made of titanium, a material known for its exceptional resistance to corrosion. Driven by the motto "There's always a better way," Hyclor is relentlessly pursuing product performance enhancements.

Q. What is the goal of Hyclor?

Hyclor's remarkable sodium hypochlorite-generating system has drawn attention for its significant 25% improvement in effective chlorine concentration over previous models.

Our product stands out as a revolutionary solution to the quality degradation issues often encountered during the storage of commercially available sodium hypochlorite. Moreover, it minimizes the maintenance requirements, making it an economically sound choice. Leveraging our cutting-edge technology, Hyclor is poised to make bold forays into the international market. Moreover, we firmly believe that South Korea's tidal power technology is highly competitive. Leveraging our experience in operating the Sihwa Lake Tidal Power Plant, the world's largest tidal power plant, we are confident that we can lead the global tidal power market, and we hope that Hyclor can play a pivotal role in this endeavor. We are committed to establishing ourselves as a trusted partner in the huge field of water treatment solutions.

Our product stands out as a revolutionary solution to the quality degradation issues often encountered during the storage of commercially available sodium hypochlorite. Moreover, it minimizes the maintenance requirements, making it an economically sound choice. Leveraging our cutting-edge technology, Hyclor is poised to make bold forays into the international market. Moreover, we firmly believe that South Korea's tidal power technology is highly competitive. Leveraging our experience in operating the Sihwa Lake Tidal Power Plant, the world's largest tidal power plant, we are confident that we can lead the global tidal power market, and we hope that Hyclor can play a pivotal role in this endeavor. We are committed to establishing ourselves as a trusted partner in the huge field of water treatment solutions.